- Home

- About us

- Products

- Filling Machine

- Labelling Machine

- Tube Filling and Sealing Machine

- Perfume Filling Machine

- Monoblock Filling Machine

- Powder Filling Machine

- Nail Polish Filling Machine

- Capping Machine

- Cartoning Machine

- Vacuum Emulsifying Machine

- Packing Machine

- Production Line

- Lipstick Filling Machine

- Syringe Filling Machine

- Coding Machine

- Induction Sealing Machine

- Bottle Unscrambling Machine

- Liquid Filling Machine

- Cream Filling Machine

- Shrinking Machine

- Faqs

- News

- Certificate

- Contact us

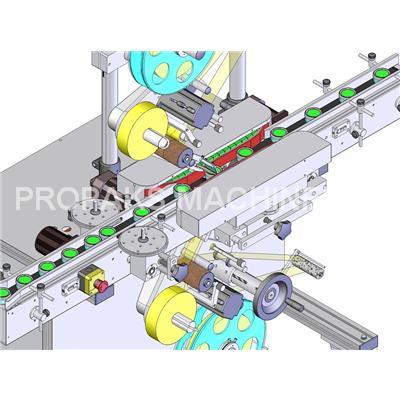

Top and Bottom Labelling Machine

time2013/08/01

Top and Bottom Labelling Machine

* This machine is suitable for label lesser height of square , round , and flat bottles in the industry of foodstuff, medicine,cosmetic and so on

* This machine the function is advance, easy operation, structure compact. Adopt to photoelectricity examine, PLC control, Touch screen software operation, conveyor belt, nip bottle belt are all stepless for speed adjust, label nicety; at the same time it has the function of no object no labeling, no label can revise by itself, and automatic to check.

* This machine can using single label, and also can using with other packing machinery for automatic produce on line.

Machine specification

top and bottom sides label speed | 40-100 units/ min(depend on material and label size) |

Top side label speed | 60-200 units/ min(depend on material and label size) |

conveyor belt speed | 5~40m/min |

Nip belt speed | 5~40m/min |

the width of conveyor belt through bottle | F20~100mm |

label out speed | 3~40m/min |

label precision (not including packing unit and label error) | ±1mm |

Max label width of Top side | 95 mm |

Max label width of bottom side | 40 mm |

Min length of label | 10mm |

total power | 2000W |

power | L/N/PE 220V 50Hz |

Using condition temperature | 0-50℃ |

Using relative humidity | 15-90% |

Label parameter

Label specs of labeling machine

a) Label paper adopt to Glassine paper(paper that can euphotic)

b) Paper thickness of label all of 25×10-6m(25mm);

c) Paper rigidity of label fit company certificate;

d) Label quality need upto company’s certificate then can using.

e) Label roll out diameter <F350;Label roll inner diameter is F760。

paper backing width A | Label width B |

<100mm | 10-95mm |